Your latest project just hit a roadblock—the industrial automation system integration documentation doesn’t meet Portland compliance standards. You’re facing costly delays and potential safety issues. Sound familiar? You’re not alone.

Many businesses across Portland face this exact challenge. In this comprehensive guide, we’ll walk you through everything you need to know about professional industrial automation system integration services and how to ensure your next project runs smoothly.

What Is Industrial Automation System Integration?

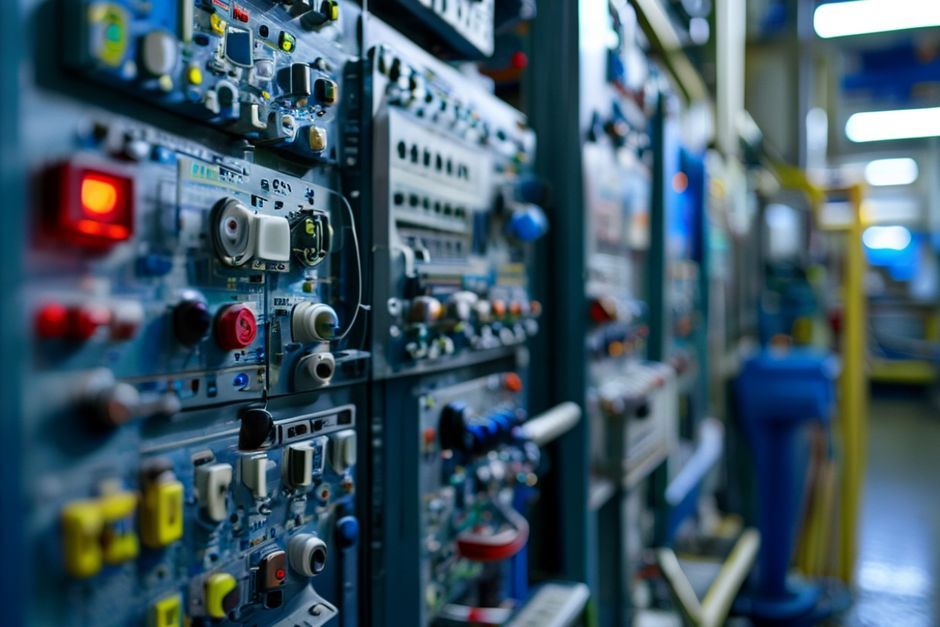

At its core, industrial automation system integration is the process of designing, implementing, and optimizing a cohesive network of intelligent control systems, sensors, and software to automate and streamline industrial processes. This holistic approach combines electrical engineering, controls engineering, data management, digital twinning, and predictive analytics to create a centralized, data-driven ecosystem that enhances operational performance.

The key components of an industrial automation system integration project include electrical design and engineering, controls engineering, data management and analytics, digital twinning, and predictive maintenance. By seamlessly integrating these core components, industrial automation system integration delivers a host of benefits that can transform the way you approach your industrial operations. For related services, see our electrical design capabilities.

Key Benefits for Portland Businesses

As a leading hub for manufacturing, mining, food processing, and construction, Portland’s industrial landscape is rife with unique challenges that make automation system integration an increasingly critical requirement. By leveraging the power of industrial automation, businesses in Portland can overcome these obstacles and position themselves for long-term success.

- Productivity and Efficiency Gains: Automation can streamline production processes, reduce downtime, and enhance overall visibility, leading to measurable gains in output, throughput, and profitability.

- Maintenance and Sustainability Improvements: Predictive analytics and condition monitoring can help businesses anticipate equipment failures, optimize maintenance schedules, and minimize their environmental impact.

- Safety and Compliance Enhancements: Automated safety controls and increased traceability can improve worker safety and assist with compliance reporting to meet the standards set by the Oregon Electrical Specialty Code, Oregon OSHA, and other relevant industry regulations.

How to Choose the Right Provider

Partnering with an experienced, reputable, and collaborative provider can mean the difference between a successful, long-lasting implementation and a costly, problematic project. When evaluating potential automation system integration partners in Portland, look for a provider with a proven track record of delivering successful projects in your specific industry, a collaborative approach, and the ability to address common challenges, such as cybersecurity and infrastructure compatibility.

Need Electrical Design & Engineering Support?

Advanced Mechanix delivers expert electrical design, CAD drafting, and engineering solutions for industrial and mining operations.

📞 +1 408 412 0717 | 📧 company@advancedmechanix.com

Industry Applications in Portland

Mining Sector

Industrial automation system integration can revolutionize mining operations in Portland by automating material extraction, streamlining logistics, and improving worker safety. By integrating advanced controls, sensors, and predictive analytics, mining facilities can achieve higher production levels, greater operational efficiency, and enhanced sustainability.

Manufacturing

For manufacturing businesses in Portland, industrial automation system integration can deliver significant gains in productivity, quality control, and energy optimization. Automated material handling, real-time process monitoring, and digital twinning can streamline workflows, reduce waste, and enhance overall equipment effectiveness (OEE).

Frequently Asked Questions

What does industrial automation system integration cost in Portland?

The investment required for industrial automation system integration in Portland can vary widely, ranging from hundreds of thousands to millions of dollars, depending on factors such as the size and complexity of your facility, the specific components and technologies required, and the level of customization and integration needed. Despite the upfront costs, the return on investment (ROI) can be substantial, with businesses in Portland typically seeing a payback period of 1-3 years and ongoing benefits for years to come.

How long does a typical project take?

The duration of an industrial automation system integration project in Portland can vary depending on the scope and complexity of the implementation. Smaller, less complex projects may be completed within 3-6 months, while larger, more comprehensive initiatives can take 6-12 months or longer. The key is to partner with an experienced provider who can develop a detailed project plan, communicate regularly with your team, and ensure a smooth, timely implementation that minimizes disruption to your operations.

Conclusion

Industrial automation system integration is a game-changer for businesses in Portland, offering unparalleled benefits in efficiency, productivity, maintenance, and sustainability. By partnering with the right experts, you can revolutionize your industrial operations and gain a competitive edge in the local market.

Ready to get started? Contact Advanced Mechanix today for a free project assessment: +1 408 412 0717 or company@advancedmechanix.com